Sustainable business

Innovating and investing in the future

Innovating and investing in the future

Concrete Valley is growing. We are a young, rapidly growing organisation, but at the same time, we want to make the concrete sector more sustainable and minimise our footprint. Concrete Valley has been working to make our concrete products more sustainable since its inception. In doing so, we take our responsibility for the climate and the targets set out in the European Climate Agreement. By applying several sustainable changes within production processes, raw materials and operations, we are working towards CO-2-free and energy-neutral production.

Concrete Valley’s goal is to create long-term sustainable value. Globally, the cement industry is considered responsible for over 7% of man-made CO2 emissions. In the Netherlands, it is less than 2%. Our ambition is to grow Concrete Valley and reduce its carbon emissions and its impact on the environment.

In short

The Concrete Sustainability Council (CSC) is committed to making concrete more sustainable worldwide and promoting more responsible production in the industry. Concrete Valley has felt this sustainable responsibility for years and is continuously looking for better ways and raw materials to produce responsibly. Beyond the sustainable adaptations, such as the construction of a solar energy system and an electric vehicle fleet, the companies within the group work with proprietary concrete mixes and innovations that sometimes involve up to eighty per cent of materials (including cement) saved without adversely affecting all the benefits concrete offers. All solutions are highly wear-resistant, low-maintenance and have the same load-bearing capacity. A distinctive feature. The Concrete Sustainability Council (CSC) has certified Concrete Valley with CSC Gold for this purpose.

In our fully computer-controlled mixing plant, we can produce around 200 m3 of concrete daily. One of the raw materials for this: cement, which we mix with ecocem (sustainable binder). As a result, less cement is needed. Through smartly devised processes and accurate measurements, the various blends are optimally designed and made. We work on that every day. We innovate with miscanthus (elephant grass), for example, and with recycled concrete granulate, which is released when old structures are demolished. We are also currently researching and testing low-CO2 binders such as geopolymer. In this, we work closely with companies with the same ambition to make our industry more sustainable.

The precise impact of our products is unveiled by the EPB, Environmental Performance Buildings. An important benchmark within sustainable construction. Not only for Civil and Non-Residential construction, this is also increasingly in demand within Land/Road/Hydraulic Engineering. All companies within our group working in these sectors have had an environmental Life Cycle Assessment (LCA) calculated, tailored to the application or product, which can be used to calculate an EPB of a design. For architects, contractors and property developers, it is exactly clear what impact our precast products will have on their projects. This promotes a responsible building culture, which we like to be at the forefront of.

Within Concrete Valley, we have set ourselves the goal of not relying on external energy from 2025. Our buildings will then no longer be heated by gas but by our own generated heat and energy.

We are also currently working on making the fleet and equipment, such as forklifts, more sustainable.

These are the four fundamental principles of our business activities. Protecting and respecting people, our employees, partners and neighbours are the foundation of the way we do business. For this, we have shared standards, processes and tools that help us manage and respect safety, the environment and our dealings with each other. We continuously strive to improve processes and to identify, minimise and, where possible, avoid impacts on society and the environment.

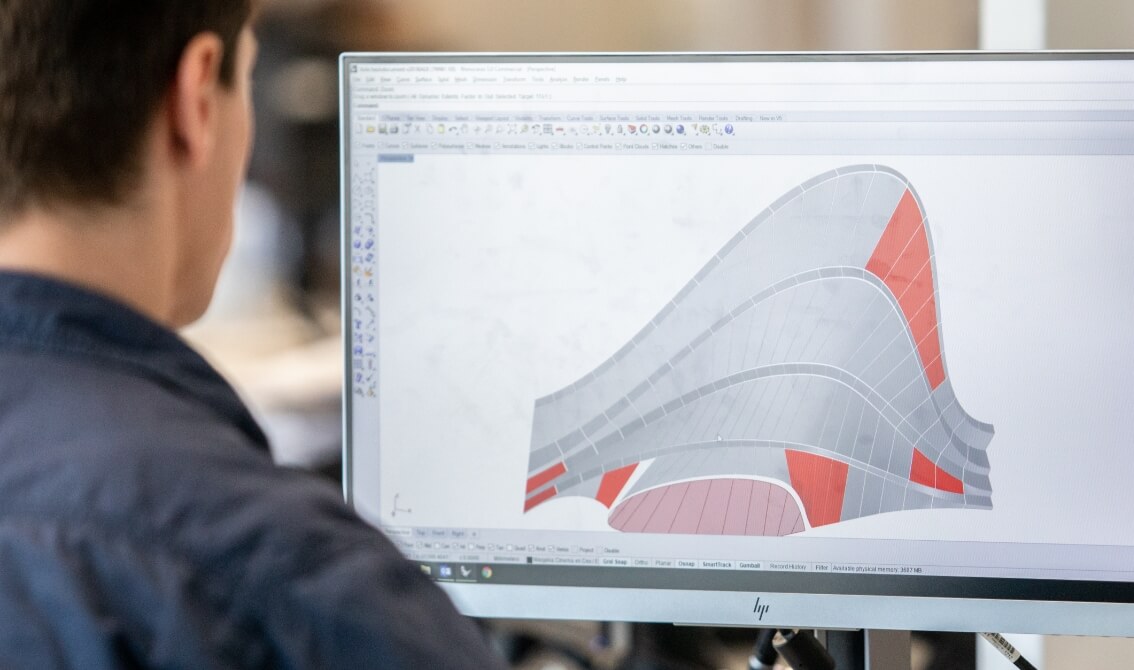

Timber Structures and Vovosa interior construction work exclusively with certified wood. Timber Structures works with flexible moulds and smart engineering, allowing us to make several different elements from a single mould. For shapes beyond the reach of the flexible mould, we use a fully optimised milling process. With sophisticated programming and the right sequence, only a few millimetres are milled away for each mould. From the waste wood, energy and raw materials are made into new wood in the form of press plates and pellets.

Concrete Valley holds ISO 9001 certification. It is the international standard for quality management systems. We are also currently working on ISO 45001, a management system that deals specifically with healthy and safe working conditions, and ISO 14001, the certificate that revolves around environmental sustainability. ISO 14001 is an important complement to CSC gold.

Naar ISO certificaat